Natural ventilation

Natural ventilation is the process of supplying and removing air through an indoor space without using mechanical systems. It refers to the flow of external air to an indoor space as a result of pressure or temperatures differences. There are two types of natural ventilation occurring in buildings: wind driven ventilation and stack ventilation. While wind is the main mechanism of wind driven ventilation, stack ventilation occurs as a result of the directional buoyancy force that results from temperature variation.[1]

Contents |

Process

The static pressure of air is the pressure in a free-flowing air stream and is depicted by isobars in weather maps. Differences in static pressure arise from global and microclimate thermal phenomena and create the air flow we call wind. Dynamic pressure is the pressure exerted when the wind comes into contact with an object such as a hill or a building and it described by the following equation [2] :

where (using SI units):

-

= dynamic pressure in pascals,

= fluid density in kg/m3 (e.g. density of air),

= fluid velocity in m/s.

The impact of wind on a building affects the ventilation and infiltration rates through it and the associated heat losses or heat gains. Wind speed increases with height and is lower towards the ground due to frictional drag.

The impact of wind on the building form creates areas of positive pressure on the windward side of a building and negative pressure on the leeward and sides of the building. Thus building shape is crucial in creating the wind pressures that will drive air flow through its apertures. In practical terms wind pressure will vary considerably creating complex air flows and turbulence by its interaction with elements of the natural environment (trees, hills) and urban context (buildings, structures). Vernacular and traditional buildings in different climatic regions rely heavily on natural ventilation for maintaining thermal comfort conditions in the enclosed spaces.

Design

Design guidelines are offered in building regulations and other related literature and include a variety of recommendations on many specific areas such as:

- Building location and orientation

- Building form and dimensions

- Indoor partitions and layout

- Window typologies, operation, location, and shapes

- Other aperture types (doors, chimneys)

- Construction methods and detailing (infiltration)

- External elements (walls, screens)

- Urban planning conditions

The following design guidelines are selected from the Whole Building Design Guide, a program of the National Institute of Building Sciences[3] :

- Maximize wind-induced ventilation by siting the ridge of a building perpendicular to the summer winds

- Widths of naturally ventilated zone should be narrow (max 13.7 m [45 feet])

- Each room should have two separate supply and exhaust openings. Locate exhaust high above inlet to maximize stack effect. Orient windows across the room and offset from each other to maximize mixing within the room while minimizing the obstructions to airflow within the room.

- Window openings should be operable by the occupants

- Consider the use of clerestories or vented skylights.

Wind driven ventilation

Wind driven ventilation depends on wind behavior, on the interactions with the building envelope and on openings or other air exchange devices such as inlets or chimneys. For a simple volume with two openings, the cross wind flow rate can be calculated using the following equation [4]:

Q=Uwind√(Cp1-Cp2)/(1/A12C12)+(1/A22C22) (1)

The knowledge of the urban climatology i.e. the wind around the buildings is crucial when evaluating the air quality and thermal comfort inside buildings as air and heat exchange depends on the wind pressure on facades. As we can see in the equation (1), the air exchange depends linearly on the wind speed in the urban place where the architectural project will be built. CFD (Computational Fluid Dynamics) tools and zonal modelings are usually used to design naturally ventilated buildings. Windcatchers are able to aid wind driven ventilation by directing air in and out of buildings.

Some of the important limitations of wind driven ventilation:

- Unpredictability and difficulties in harnessing due to speed and direction variations

- The quality of air it introduces in buildings may be polluted for example due to proximity to an urban or industrial area

- May create a strong draught, discomfort.

Stack driven ventilation

-

- (For more details, see Stack effect)

Stack effect is temperature induced. When there is a temperature difference between two adjoining volumes of air the warmer air will have lower density and be more buoyant thus will rise above the cold air creating an upward air stream. Forced stack effect in a building takes place in a traditional fire place. Passive stack ventilators are common in most bathrooms and other type of spaces without direct access to the outdoors.

In order for a building to be ventilated adequately via stack effect the inside and outside temperatures must be different so that warmer indoor air rises and escapes the building at higher apertures, while colder, denser air from the exterior enters the building through lower level openings. Stack effect increases with greater temperature difference and increased height between the higher and lower apertures. The neutral plane in a building occurs at the location between the high and low openings at which the internal pressure will be the same as the external pressure (in the absence of wind). Above the neutral plane, the air pressure will be positive and air will rise. Below the neutral plane the air pressure will be negative and external air will be drawn into the space. Stack driven ventilation has several significant benefits:

- Does not rely on wind: can take place on still, hot summer days when it is most needed.

- Stable air flow (compared to wind)

- Greater control in choosing areas of air intake

- Sustainable method

Limitations of stack driven ventilation:

- Lower magnitude compared to wind ventilation

- Relies on temperature differences (inside/outside)

- Design restrictions (height, location of apertures) and may incur extra costs (ventilator stacks, taller spaces)

- The quality of air it introduces in buildings may be polluted for example due to proximity to an urban or industrial area

Natural ventilation in buildings relies mostly in wind pressure differences but stack effect can augment this type of ventilation and partly restore air flow rates during hot, still days. Stack ventilation can be implemented in ways that air inflow in the building does not rely solely on wind direction. In this respect it may provide improved air quality in some types of polluted environments such as cities. For example air can be drawn through the backside or courtyards of buildings avoiding the direct pollution and noise of the street facade. Wind can augment the stack effect but also reduce its effect depending on its speed, direction and the design of air inlets and outlets. Therefore prevailing winds must be taken into account when designing for stack effect ventilation.

Estimating stack effect ventilation

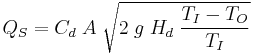

The natural ventilation flow rate can be estimated with this equation:[4]

-

where: QS = Stack vent airflow rate, ft³/s A = cross-sectional area of opening, ft² (assumes equal area for inlet and outlet) Cd = Discharge coefficient for opening (typical value is 0,62) g = gravitational acceleration, around 32.2 ft/s² on Earth Hd = Height from midpoint of lower opening to neutral pressure level (NPL), ft NPL

= location/s in the building envelope with no pressure difference between inside and outside (ASHRAE 2001, p. 26.11) TI = Average indoor temperature between the inlet and outlet, °R TO = Outdoor temperature, °R

-

where: QS = Stack vent airflow rate, m³/s A = cross-sectional area of opening, m² (assumes equal area for inlet and outlet) Cd = Discharge coefficient for opening (typical value is 0,62) g = gravitational acceleration, around 9.81 m/s² on Earth Hd = Height from midpoint of lower opening to neutral pressure level (NPL), m NPL

= location/s in the building envelope with no pressure difference between inside and outside (ASHRAE 2001, p. 26.11) TI = Average indoor temperature between the inlet and outlet, K TO = Outdoor temperature, K

Assessing performance

One way to measure the performance of a naturally ventilated space is to measure the air changes per hour in an interior space. In order for ventilation to be effective, there must be exchange between outdoor air and room air. A common method for measuring ventilation effectiveness is to use a tracer gas.[5] The first step is to close all windows, doors, and openings in the space. Then, a tracer gas is added to the air. The reference, American Society for Testing and Materials (ASTM) Standard E741: Standard Test Method for Determining Air Change in a Single Zone by Means of a Tracer Gas Dilution, describes which tracer gases can be used for this kind of testing and provides information about the chemical properties, health impacts, and ease of detection.[6] Once the tracer gas has been added, mixing fans can be used to distribute the tracer gas as uniformly as possible throughout the space. To do a decay test, the concentration of the tracer gas is first measured when the concentration of the tracer gas is constant. Windows and doors are then opened and the concentration of the tracer gas in the space is measured at regular time intervals to determine the decay rate of the tracer gas. The airflow can be deduced by looking at the change in concentration of the tracer gas over time. For further details on this test method, refer to ASTM Standard E741.[6]

Standards

For standards relating to ventilation rates, in the United Stated refer to ASHRAE Standard 62.1-2010: Ventilation for Acceptable Indoor Air Quality.[7] These requirements are for "all spaces intended for human occupancy except those within single-family houses, multifamily structures of three stories or fewer above grade, vehicles, and aircraft."[7] In the revision to the standard in 2010, Section 6.4 was modified to specify that most buildings designed to have systems to naturally condition spaces must also "include a mechanical ventilation system designed to meet the Ventilation Rate or IAQ procedures [in ASHRAE 62.1-2010]. The mechanical system is to be used when windows are closed due to extreme outdoor temperatures noise and security concerns".[7] The standard states that two exceptions in which naturally conditioned buildings do not require mechanical systems are when:

- Natural ventilation openings that comply with the requirements of Section 6.4 are permanently open or have controls that prevent the openings from being closed during period of expected occupancy, or

- The zone is not served by heating or cooling equipment.

Also, an authority having jurisdiction may allow for the design of conditioning system that does not have a mechanical system but relies only on natural systems.[7] In reference for how controls of conditioning systems should be designed, the standard states that they must take into consideration measures to "properly coordinate operation of the natural and mechanical ventilation systems."[7]

Another reference is ASHRAE Standard 62.2-2010: Ventilation and Acceptable Indoor Air Quality in low-rise Residential Buildings.[8] These requirements are for "single-family houses and multifamily structures of three stories or fewer above grade, including manufactured and modular houses," but is not applicable "to transient housing such as hotels, motels, nursing homes, dormitories, or jails."[8]

For standards relating to ventilation rates, in the United Stated refer to ASHRAE Standard 55-2010: Thermal Environmental Conditions for Human Occupancy.[9] Throughout its revisions, its scope has been consistent with its currently articulated purpose, “to specify the combinations of indoor thermal environmental factors and personal factors that will produce thermal environmental conditions acceptable to a majority of the occupants within the space.”[9] The standard was revised in 2004 after field study results from the ASHRAE research project, RP-884: developing an adaptive model of thermal comfort and preference, indicated that there are differences between naturally and mechanically conditioned spaces with regards to occupant thermal response, change in clothing, availability of control, and shifts in occupant expectations.[10] The addition to the standard, 5.3: Optional Method For Determining Acceptable Thermal Conditions in Naturally Ventilated Spaces, uses an adaptive thermal comfort approach for naturally conditioned buildings by specifying acceptable operative temperature ranges for naturally conditioned spaces.[9] As a result, the design of natural ventilation systems became more feasible, which was acknowledged by ASHRAE as a way to further sustainable, energy efficient, and occupant-friendly design.[9]

See also

- Ventilation (architecture)

- Infiltration (HVAC)

- Air-side economizers

- Solar chimney

- Windcatcher

- Indoor air quality

- Sick building syndrome

- Heating, Ventilation and Air-Conditioning

- Mechanical engineering

- Architectural engineering

- Green building

- Passive cooling

- Mixed Mode Ventilation

- Room air distribution

- Thermal comfort

- air conditioning

- ASHRAE

- Glossary of HVAC

References

- ^ Linden, P. F. (1999). "The Fluid Mechanics of Natural Ventilation". Annual Review of Fluid Mechanics 31: 201–238. doi:10.1146/annurev.fluid.31.1.201.

- ^ Clancy, L.J. (1975). Aerodynamics. John Wiley & Sons.

- ^ Walker, Andy. "Natural Ventilation". National Institute of Building Sciences. http://www.wbdg.org/resources/naturalventilation.php.

- ^ a b ASHRAE Handbook. Atlanta, GA: American Society of Heating, Refrigerating and Air Conditioning Engineers. 2009.

- ^ McWilliams, Jennifer (2002). "Review of air flow measurement techniques. LBNL Paper LBNL-49747.". Lawrence Berkeley National Lab. http://escholarship.org/uc/item/7532b84f?query=Review%20of%20air%20flow%20measurement%20techniques.

- ^ a b ASTM Standard E741-11: Standard Test Method for Determining Air Change in a Single Zone by Means of a Tracer Gas Dilution. West Conshohocken, PA: ASTM International. 2006.

- ^ a b c d e ANSI/ASHRAE Standard 62.1-2010: Ventilation for Acceptable Indoor Air Quality. Atlanta, GA: American Society of Heating, Refrigerating and Air-Conditioning Engineers. 2010.

- ^ a b ANSI/ASHRAE Standard 62.2-2010: Ventilation and Acceptable Indoor Air Quality in Low-Rise Residential Buildings. Atlanta, GA: American Society of Heating, Refrigerating and Air-Conditioning Engineers. 2010.

- ^ a b c d ANSI/ASHRAE Standard 55-2010: Thermal Environmental Conditions for Human Occupancy. Atlanta, GA: American Society of Heating, Refrigerating and Air-Conditioning Engineers. 2010.

- ^ de Dear, Richard J.; Gail S. Brager (2002). "Thermal Comfort in Naturally Ventilated Buildings: Revisions to ASHRAE Standard 55.". Energy and Buildings 34 (6). doi:10.1016/S0378-7788(02)00005-1.

External links

University-based research centers that currently conduct natural ventilation research:

- The Center for the Built Environment (CBE), University of California, Berkeley. http://www.cbe.berkeley.edu/

- Lawrence Berkeley National Laboratory, Berkeley, California. http://www.lbl.gov/

- Department of Architecture, Massachusetts Institute of Technology. http://architecture.mit.edu/building-technology/program/research-topics

- Faculty of Architecture, Design and Planning, University of Sydney, Australia. http://sydney.edu.au/architecture/research/research_archdessci.shtml

Natural Ventilation Guidelines:

- Whole Building Design Guide, National Institute of Building Sciences http://www.wbdg.org/resources/naturalventilation.php

- "Natural Ventilation for Infection Control in Health-Care Settings," a report (including design guidelines) by World Health Organization for naturally ventilated health-care facilities.http://whqlibdoc.who.int/publications/2009/9789241547857_eng.pdf